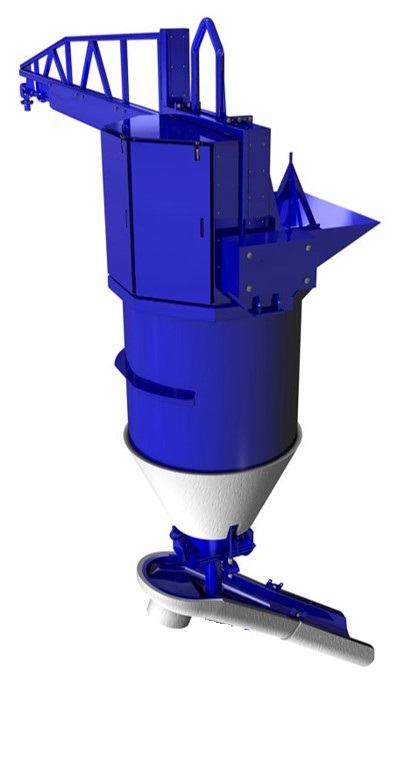

Spreader – Fettling Machine

It shall be fed with refractory mix big-bags by overcame, where can be used both valve big-bags and by ripping. The application of the material on the EAF button or banks made by lifting the machine inside the EAF by using a crane and operating its chute that round 360º. The material goes down from the machine through the chute by gravity. With both chute rotation and overcame translation, it is possible to repair any area of the heart and banks areas. Both operation of the chute and the material door (that releases the refractory mix) completely made by remote control (wireless or pneumatic control panel) that allows to the operator a perfect view of the areas to be repaired at a safe distance from the heat.

- Width: 7,8 m, including the arm (hose support);

- Length: 2,0 m;

- High: 5,6 to 5,9 m;

- Weight: 2,5 ton;

- Hopper Capacity: 2, 4 or 6 tons;

- Chute rotation speed: 5 to 10 rpm (adjustable );

- Chute rotation radius: 1,7 radius;

- Engine Power: 0,5 to 2,0 HP;

- Material door opening and Chute Opening, controlled by remote control;

- Precise application of the fettling mix to the bank and heart areas;

- Dust-free processing of the fettling mix;

- Minimizes segregation of the fettling mix during operation;

- Improve service life and reduced mix consumption;

- Time saving through high flow rate and precise mix application;

- BIG BAG charging;

- Easy to use

- Minimum pressure operation: 5 kgf/cm²;

- Air consume: 4m³/min;

- Air feeding hose diameter: ¾”