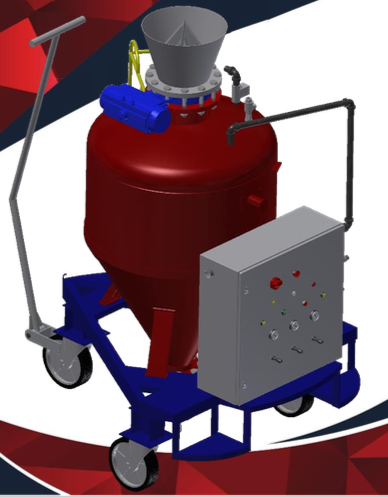

Refractory Gunning Machine – Pneumatic Control

Material (tank)

- Maximum particle size: 3,5 mm

- Maximum Pressure: 3,4 kg/cm ²

- Maximum Output: 100 kg/min.

- Maximum Load: 1.000 kg

Air

- Maximum working pressure: 5 kg/cm²

- Air Consume: 5 m³/min.

- Dimensions: 1778 x 1420 x 2166 mm

- Weight: 1100 kg

- Inlet and outlet Butterfly valves pneumatic operated;

- Easy to operate with less physical strain;

- Can be loaded with sacs or big-bag (under-consultation);

- Does not use electronic components;

- Simple design, robust and easy to operate;

- High durability low maintenance level;

- As the water/refractory mix is made in the nozzle, there is no clogging inside the hose, thus allowing consecutive gunning;

- Mounted over a car equipped with 03 wheels – easy to move;

- Constant projection volume (up to 150 kg / min);

- Has safety valve to prevent accidents due to overpressure;