Ladle Hot Spot Detection

Thermography-based Ladle Monitoring System

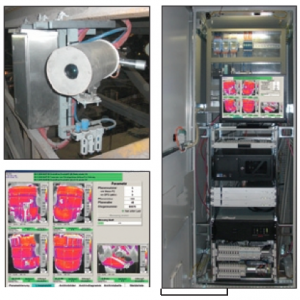

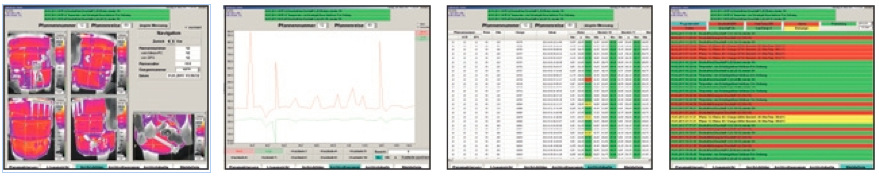

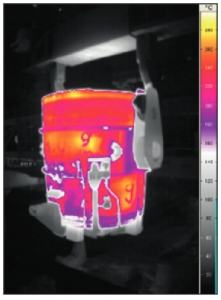

The Ladle Hot Spot Detection (LHSD) system uses Infrared (IR) technology to monitor the temperature of the ladle steel structure. Five thermography cameras observe the ladles while they are moved with the crane to the casting. The temperature measurements are made fully automatically without the need of any manual interaction. Optionally the ladle number can be recognised from characters on their surface. LHSD automatically raises the alarm if an adjustable temperature threshold is overrun. This reliably prevents dangerous and loss-making breakouts of liquid steel. LHSD automatically tracks the temperature development of all ladles in circulation. This allows to maximize the ladle refractory lifetime without cutback of security and helps to save remarkable costs. LHSD comes with highly reliable components in a flexible structure and thus is easily adoptable to the different situations and operational modes in steel plants.

The Ladle Hot Spot Detection (LHSD) system uses Infrared (IR) technology to monitor the temperature of the ladle steel structure. Five thermography cameras observe the ladles while they are moved with the crane to the casting. The temperature measurements are made fully automatically without the need of any manual interaction. Optionally the ladle number can be recognised from characters on their surface. LHSD automatically raises the alarm if an adjustable temperature threshold is overrun. This reliably prevents dangerous and loss-making breakouts of liquid steel. LHSD automatically tracks the temperature development of all ladles in circulation. This allows to maximize the ladle refractory lifetime without cutback of security and helps to save remarkable costs. LHSD comes with highly reliable components in a flexible structure and thus is easily adoptable to the different situations and operational modes in steel plants.